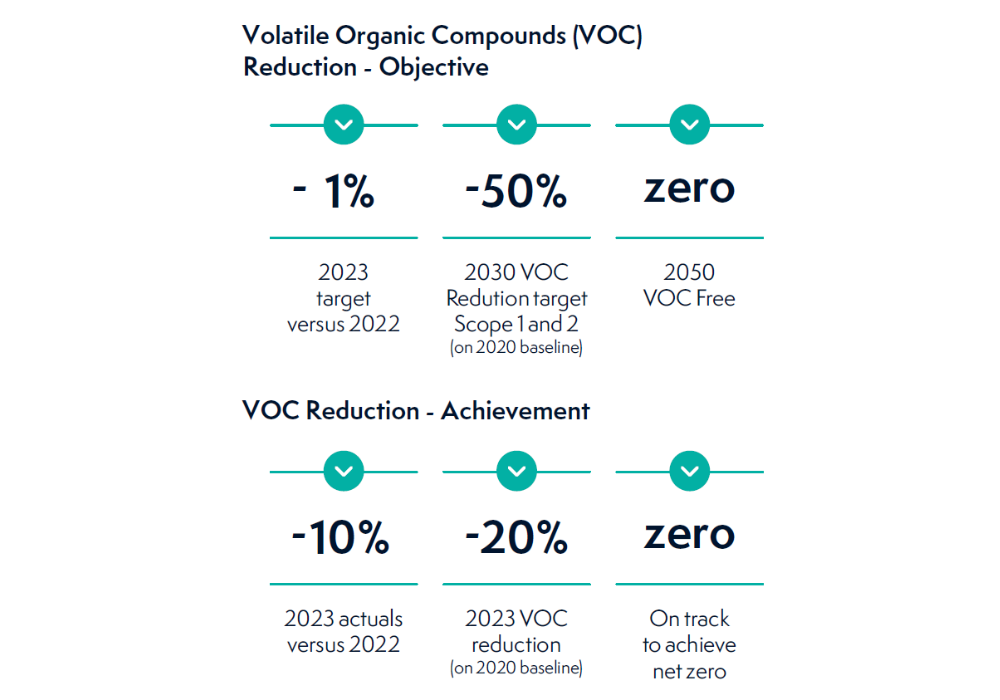

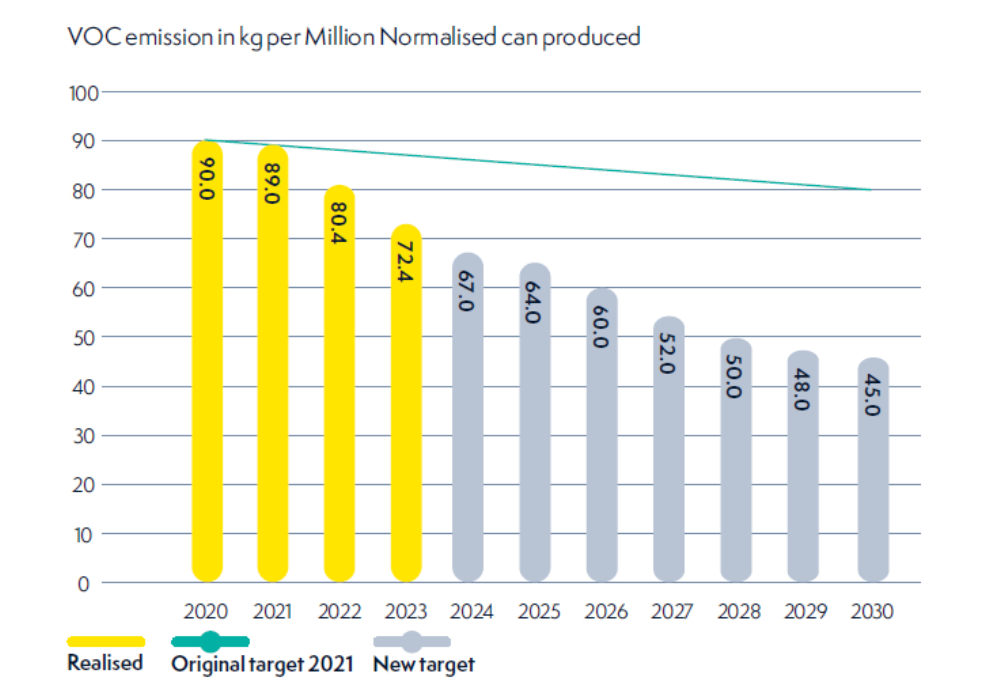

VOC reduction objective

At Sonoco Metal Packaging EMEA we reduce solvents through various means, including changing processes, increasing our use of water-based products, and modernising or adding incinerators and oxidisers. We invest millions of euros each year to increase the number of new generation oxidisers across our plants with the capacity to convert solvents into fuel. During the polymerisation of our coatings in the ovens, solvent emissions are recovered by the oxidiser to be used as fuel. The heat generated is then reinjected into the oven. This circular process enables us to save up to 50% of gas used for combustion. The superior performance of the new incinerators also enables further elimination of solvent use in the manufacturing process.

2023 VOC reduction achievements

In 2023, Sonoco Metal Packaging EMEA reduced its solvents by 10% compared to the levels reported in 2022. We are proud to report that in 2023 we exceeded our objectives for the reduction of VOC emissions, reducing them by 20% compared to our baseline year (2020), four years ahead of plan, thanks to the 5 incinerators implemented in the previous year and delivering their performance in 2023.

Action plan for the future

Sonoco Metal Packaging EMEA

• As with GHG emissions, at Sonoco Metal Packaging EMEA we have reviewed our targets, and established new more aggressive VOC reduction objectives. Our new targets aim to reduce VOC emissions 50% by 2030, and to reach net zero by 2050.

• Sonoco Metal Packaging EMEA plan to continue to reduce the use of solvents, gradually adopting new coatings for our products. This will be enabled further as we increasingly transition to Ultra Violet (UV) coating.

• Sonoco Metal Packaging EMEA will continue to invest in solvent-free machines to clean our coating equipment, which will enable the elimination of an additional 2.5 tonnes of solvent annually.

Waste management

Since 2021, at Sonoco Metal Packaging EMEA we have continuously measured our waste generation in line with the European Waste Codification (EWC) guidelines. This precise monitoring system enables us to measure our recycling performance. We can therefore report with confidence that in 2023 we recycled 95.4% of our total waste. We recycled 78.6% of our hazardous waste, with the balance used as fuel for other industries. Sonoco Metal Packaging EMEA continuously explores new ways to reduce the waste we produce. We recycle all cardboard, plastic, and 100% of metal scrap waste. We separate and treat potentially hazardous materials — such as solvents, inks, and varnishes — and turn them over to specialised contractors who ensure their appropriate treatment. None of the hazardous or potentially toxic materials we use in our production process are returned to nature. Details of the hazardous waste categories we manage are available in Sonoco Metal Packaging EMEA’s SASB index in the Appendix of this report.

2023 achievements

During the year, at Sonoco Metal Packaging EMEA we continued to analyse all waste sent from our plants across the world. We also continued the process of standardising waste management procedures across all our sites with the aim of eliminating waste to landfill in all our locations by 2025. These standards and processes enabled us to attain the high levels of recycling we reported in 2023. For waste that we are not able to recycle, we work with certified partners to find solutions for re-valuing it or converting it to fuel for industrial use. As further examples of our accomplishments in 2023, two of our plants received Zero Waste to Landfill

Certificates: Sonoco Metal Packaging EMEA’s site in Murcia, Spain , and site in Mansfield, England. (see copy of certificate in our ESG report here)

Action Plan for the Future

At Sonoco Metal Packaging EMEA we will continue to work toward achieving our goal of Zero Waste to Landfill at 100% of our sites by 2025.