Reducing our direct emissions and energy consumption

Sonoco Metal Packaging EMEA outperformed its scope 1 and 2 GHG emissions reduction targets

We are pleased to report that at Sonoco Metal Packaging EMEA we surpassed our original Scope 1 and 2 emissions targets for 2023, underscoring the effectiveness of the measures we have taken at our plants and across the company. During the year, we achieved a reduction of circa 20% of emissions versus 2020 (our baseline year), a full four years ahead of the original plan. Therefore, given our better-than-expected performance against objectives, we have reviewed our original targets and have chosen to challenge ourselves to continue to outperform by establishing new, more ambitious emissions reduction targets.

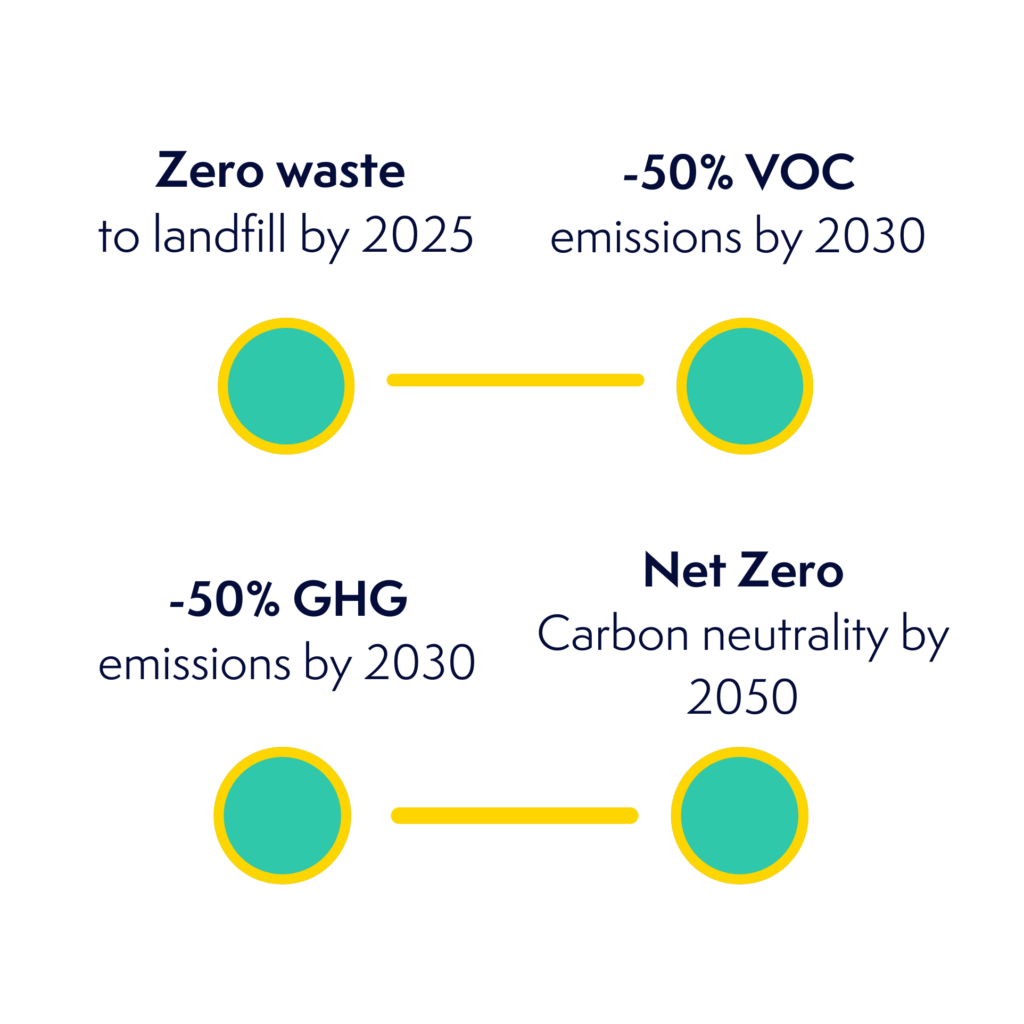

Our new targets call for reducing our Scope 1 and 2 emissions 50% by the year 2030, and reaching net zero emissions by 2050

We have reduced our medium-term targets for Scope 1 and 2 GHG emissions to 4.7 tonnes per million of normalised cans by 2030 (from the previous target of 6.85).

During the year 2023 we took two major steps on our climate strategy journey:

- We submitted our first report to the Climate Disclosure Project (CDP)

- We established new emission reduction objectives, which were submitted to the Science Based Targets initiative (SBTi). We are now committed to the SBTi’s net zero standard, and await validation of our objectives. It should be noted that in our reporting, we increase our Scope 1 and 2 data by 15% above actual values to cover any under estimation in the calculation of our GHG and air emissions (all calculations follow location-based protocols).

- Additionally, Scope 2 emissions also include Transmission and Distribution values. All our results are verified by Bureau Veritas and aligned with ISAE 3000 reporting methods. Certifications available in our ESG report here.

During the year 2023, Sonoco Metal Packaging EMEA continued to focus on reducing Scope 1 and 2 GHG emissions (direct emissions from fossil fuel, and indirect emissions from electricity used, respectively). We also monitored closely the key performance indicator for air quality regarding the solvent emissions from our activities.

Renewable Energy

In 2023, the electricity we used from renewable sources totalled 2.46% of all the energy we consumed during the year, the same level as we reported in 2022. We transitioned to a higher level of solar energy use in 2024, thanks to our new installations in Battipaglia (2022), Merida (2023), and Murcia (2023).

Our solar capacity program is set to continue over the next several years. Following is the detail of solar energy capacity Sonoco Metal Packaging EMEA installed in 2023:

• At Sonoco Metal Packaging EMEA’s largest plant, located in Murcia, Spain we installed solar panels to supply 18% of our energy needs at that facility. With 7,912 panels of 660 watts each, or the capacity to produce 5.2 MegaWatts/hour, this installation will enable us to reduce our overall Scope 2 GHG emissions by 2,212 tonnes of CO2 per year. The installation, which encompasses 15 inverters, two transformer substations, and a high-voltage electrical line, also includes roof safety infrastructure such as safety lines, walkways, and staircases. Sonoco Metal Packaging EMEA’s solar panel project in Murcia is one of the largest such projects in Spain.

• Sonoco Metal Packaging EMEA also installed solar panels at its plant in Mérida, Extremadura, Spain. The 2,596 panels, which are installed on the roof of a warehouse and close to high voltage transformers, enable our plant to produce 35% of its energy needs, and enable the reduction of 456 tonnes of CO2 per year. Other emission reduction activities during the year encompassed:

• Replacing liquefied petroleum gas (LPG) forklifts with electric ones with the objective of saving an estimated 10 tonnes of CO2 per machine per year. At year-end 2023, 77% of forklifts used across Sonoco Metal Packaging EMEA were electric.

• Continuing with our campaign to switch to LED lighting on all our factory floors. During the year we achieved 80% coverage of our lighting needs, with the aim of reaching 100% of our facilities in 2027. This will enable us to save up to 90% of electricity related to lighting.

• On the product offering side, we work on a continuous basis to reduce the thickness of our products through a downgauging process – while ensuring that we are not compromising on quality or performance — in an effort to reduce emissions from manufacturing and transportation.

ESG Report 2023

Explore our ESG Sustainability Report for 2023 to learn more about our commitment to Environmental, Social, and Governance actions aimed at fostering a sustainable future.